Categories

3D Fiberglass Fabric

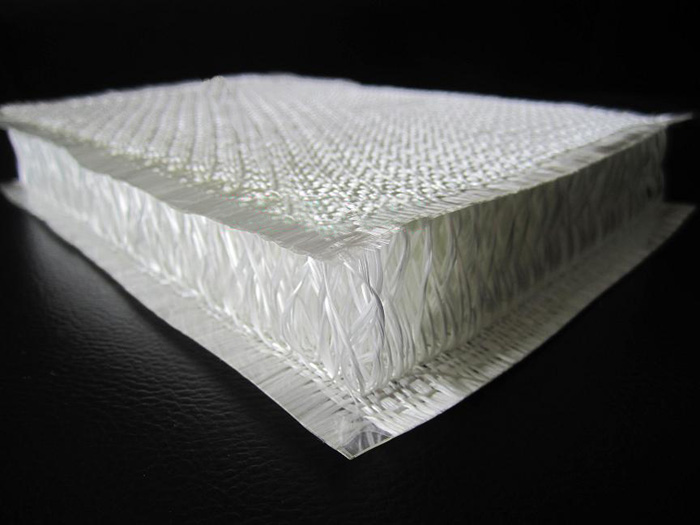

Topweaving 3D fiberglass fabric is woven from E-glass yarn and consists of two surface (deck) layers connected together by vertical links (piles). These links are woven together with the surface layers thus forming an integrated sandwich structure.

![]()

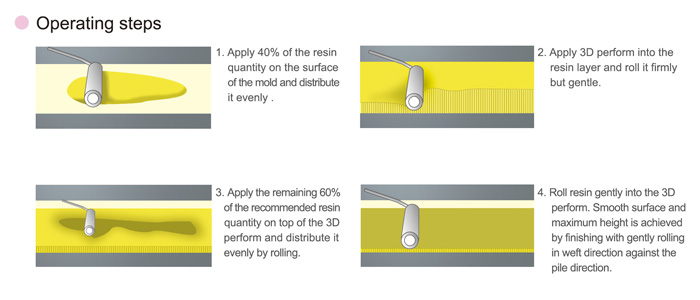

When a thermoset resin such as vinylester or epoxy was added to the Topweaving 3D fabric and lightly rolled, the surface fabric will be impregnated with the resin. Capillary action also wets out the connecting links, so that when the fabric rebounds to its full height a hollow core is formed (much like the tree trunks in a forest).This one-step process forms a sandwich laminate that offers excellent strength, stiffness, light weight and durability..

During impregnation the fabric is compressed but immediately rebounds to its original height, resulting in a lightweight sandwich laminate. This sandwich laminate forms the basis of the most technology-advanced applications. The integral sandwich concept in which core and faces are integrated to build sandwich laminates from 3 to 22 mm..

Features:

1.Light weight, High stiffness

The weight is about 30% to 60% lighter than chopped strand mat and glass roving fabrics of the same thickness.

2.Simple and effective lamination process

3D glass fabric is time and materials saving, which can be made in one step to achieve the thickness(10mm/15mm/22mm...) because of its integral structure and thickness.

3.Outstanding performance in resisitance to delamination

3D glass fabric consists of two deck layers bonded together by vertical piles, these piles are woven into the deck layers thus it can form an integral sandwich structure.

4.Easy to make an angle curve

One advantage is its highly shapeable characteristic; the most drapeable of sandwich structure can conform very easily around the contoured surfaces.

5.Hollow structure

Space between both deck layers can be multifunctional , which can monitor leakage. (embedded with sensors and wires or infused with foam)

6.High design-versatility

Piles density ,height of the piles ,the thickness all could be adjusted.

Applications:

// Double wall Underground Tanks // Interstitial Space of the Tank Lining

// Marble Panel with 3D Fiberglass // Exterior and interior wall decoration board // Dome

// Fuselage // Wing skins // Propeller and flying surfaces

// Pantograph air deflector // Air conditioning air deflector // Wallboard // Partitions // Toilet Cabins